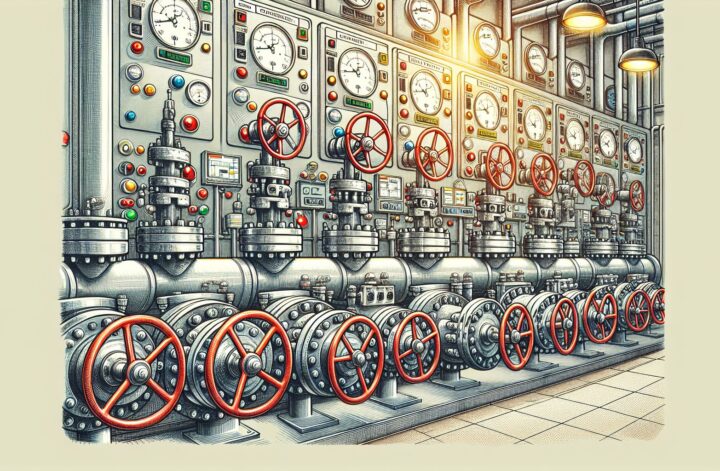

Just like every other mechanical or electrical device, valve control systems require regular maintenance to keep them in peak performance condition. Sure, the importance of valve control systems in industries can’t be overstated. They are a key element in most physical systems, having a vital role in controlling the flow and pressure of liquids and gases. However, without regular valve control maintenance, their efficiency reduces and can potentially be a cause for unexpected downtime, leading to losses.

Why Valve Control Maintenance is Crucial

Valves are imperative in controlling the flow of fluids and gasses in an industrial setting. Their effective functioning can mean the difference between an optimally running system and one that is inefficient or even potentially dangerous. A lack of proper maintenance of valve control systems can lead to leaks, flow control issues, and even catastrophic system failures.

Regular maintenance ensures:

• Reliability: A well-maintained valve control system is reliable, providing peace of mind that there’s less risk of unexpected downtime and related costs.

• Efficiency: Routine maintenance ensures the valve controls are working efficiently, thereby saving energy and decreasing operational costs.

• Life Span: Continuous maintenance increases the lifespan of the valve control systems, saving companies expensive replacement costs in the long run.

• Safety: A faulty valve may result in leaks or complete breaches, leading to dangerous incidences. Thus, regular maintenance ensures safety.

Maintenance Tips

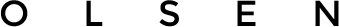

Below are some key elements to consider in maintaining valve control systems:

• Regular Inspection: Implement regular checks to identify potential issues before they escalate. Inspections should not only focus on the valve but also peripherals like positioners, actuators, etc.

• Servicing & Cleaning: All mechanical components require lubrication and cleaning. Same goes with valve control systems.

• Calibration: Regular calibration ensures that the valve control system is functioning accurately, with the response to inputs being both appropriate and predictable.

• Test Runs: An effective maintenance procedure involves periodic test runs to check system performance under different operating conditions.

• Updating and Upgrades: Stay updated on the latest technologies, and ensure your system is upgraded as necessary. Technological advancements can increase efficiency and productivity.

Valve Control Maintenance Best Practices

Every industry-specific valve control system will have its unique set of maintenance requirements, but a few best practices are universally applicable:

1. Develop a maintenance plan: Your plan should include a checklist of inspections, cleaning procedures, tests, and updates to be done regularly.

2. Use condition-monitoring tools: Predictive maintenance plays a key role in preventing premature failure or damage. Advanced tools today can help monitor everything from temperature, pressure, and flow, to acoustic emissions and even electrical properties.

3. Documentation: It’s essential to have all maintenance activities documented for future review and analysis. This can provide insight into patterns and potential issues.

4. Training: Ensure that personnel handling the maintenance are well trained and understand how valve control systems work and the essential guidelines for their maintenance.

5. Timely repairs: If any anomalies are found during maintenance checks, they should be addressed immediately to prevent further damage.

Valve control maintenance can be seen as an insurance policy: a small investment in time and resources now can prevent more serious issues further down the line. By ensuring that valve control systems are regularly inspected and maintained, the overall performance, efficiency, and longevity of the system is significantly increased. Regular valve control maintenance is, thus, a critical element of operations that shouldn’t be overlooked.

A great source of information on valve control maintenance is the “Industrial Valve Maintenance & Repair Manual” provided by Valves Incorporated [^1]. Additionally, “Maintenance Planning and Scheduling Handbook” by Richard D. Palmer [^2] offers valuable insights and suggestions on how to develop an effective maintenance plan.

Bottom line, like many things in life, an ounce of prevention is worth a pound of cure, especially when it comes to valve control maintenance.

[^1]: Valves Incorporated, “Industrial Valve Maintenance & Repair Manual.” [Online]. Available: http://www.valvesinc.com/industrial-valve-maintenance-repair-manual.pdf.

[^2]: R. D. Palmer, “Maintenance Planning and Scheduling Handbook,” McGraw Hill Professional, 2012. [Online]. Available: https://www.mhprofessional.com/9780071784115-usa-maintenance-planning-and-scheduling-handbook.