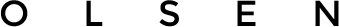

Welcome to the world of valve control automation — a sphere where the intersection of technology and manufacturing converge to enhance productivity, efficiency, and safety in various industries. From oil and gas to utilities, chemical plants, and even breweries, automated valve control has revolutionized countless industrial processes.

Introduction to Valve Control Automation

You might ask, what exactly is valve control automation? Simply put, it is the application of technology to control the flow of fluids or gases within a system, using automated valves instead of manually operated ones. This smart technology monitors the movement while providing realtime diagnostics, leading to improved safety, reduced human error, and increased efficiency[^1^].

A well-designed valve control automation system can offer significant benefits. These benefits include accuracy, precision, reduced operational costs, and the elimination of labor-intensive activities. As an industry that values accuracy and precision, it’s no wonder the demand for automated valve controls is on the rise.

Working Principle

To understand the working of valve control automation, let’s break it down. The heart of the system is the automated valve, designed to be actuated remotely using electric, pneumatic, or hydraulic energy. This action opens or closes the valve based on information received from a control system.

The information is transmitted via control software, where specific algorithms dictate the valve’s response to various scenarios. The software can adjust the valve in response to various factors such as flow rate, temperature, or pressure. These automation strategies ensure the operations proceed smoothly, while also providing feedback for system optimization.

Advantages of Valve Control Automation

1. Increased Precision and Accuracy: Automated valve controls are designed to operate with a high level of precision. They are programmed to respond to small variations in conditions, which allows for more accurate control compared to manual systems.

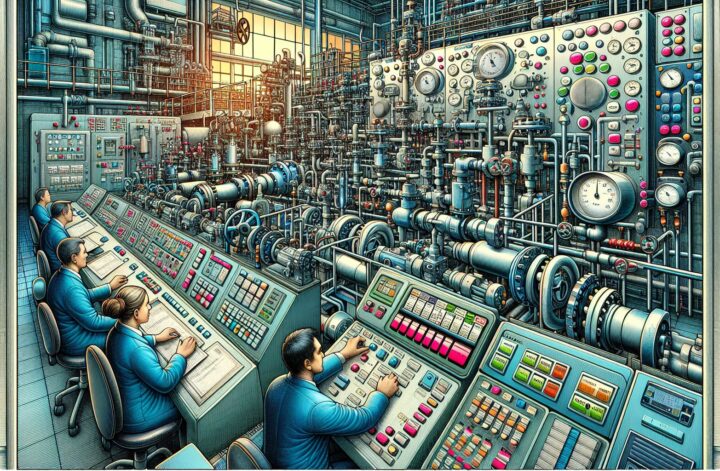

2. Safety: Automated valves can gracefully handle extreme conditions that might be risky for manual operational systems. Since the process is automated, human interaction with the system is significantly reduced, thus eliminating associated safety risks.

3. Efficiency: Automation reduces the necessity for continuous monitoring and intervention by operational staff. The valves can operate around the clock without human intervention.[^2^]

4. Cost Savings: While initial setup costs may be high, the long-term benefits result in substantial cost savings due to increased efficiency, reduced operational costs, and lower maintenance costs.

5. Flexibility: Automated valve control systems are scalable and adaptable. They can be integrated into existing systems or built from scratch, offering flexibility that’s beneficial for expanding operations or upgrading older systems.

Concluding Thoughts

To stay competitive in the industrial field, embracing technology like valve control automation is not just an option; it’s a necessity. By increasing precision, improving safety, enhancing efficiency, offering cost savings, and providing flexibility, valve control automation has unarguably made its mark in modern industrial operations.

While selecting and implementing automated valve control may seem like a daunting step, several professional service providers can help you understand your needs, guide you in the selection process, and assist in implementation and training.

Valve control automation has truly revolutionized numerous industries, offering significant advantages over traditional manual systems. By investing in this technology, organizations can ensure they stay on the cutting edge of efficiency and productivity – both today and in the future.

[^1^]: The Importance of Automated Valve Packages

[^2^]: Why Do We Need Automated Valves?