In the industrial world, we’ve come to rely heavily on automated systems for safe, reliable, and efficient operation. Of these systems, valve control is of huge importance, directly impacting the functionality of pipelines, factories, power plants, and various other industries. Yet, the reliability of these systems is undermined when there is no plan B for when things go wrong. Consequently, there is a growing emphasis on the concept of valve control redundancy.

Valve control redundancy refers to having backup or secondary valve control systems in place to step in when the primary system fails. This is a crucial aspect of maintaining consistent performance and avoiding system failures that can result in downtime or accidents.

The Importance of Redundancy in Valve Control

Picture a factory with a complex assembly line. A single failure of equipment in one section of the assembly line can halt the entire production process, leading to a slowdown in output and potentially severe financial loss. Now, imagine if this equipment had a backup system that automatically took over when the primary system failed. There would be minimal downtime, if any, allowing operations to continue without interruption. This is the essence of redundancy.

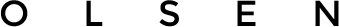

The same applies to valve control systems. Unforeseen issues, component wear and tear, software glitches, power outages, to name a few, can all render a valve control system inoperable. This is where redundant systems play a vital role. A redundant valve control system can immediately take over control, ensuring the continued safe and efficient management of fluid flow within pipelines, thus averting any disastrous consequences.

Realizing the Redundant Control Systems

There are different ways to implement redundancy in valve control systems, depending on the level of backup required. For some industries, a dual-redundant system might be adequate, where two identical systems run side-by-side. If one goes offline, the other continues to function seamlessly.

For environments where there’s a higher risk or higher costs associated with a system failure, triple-redundant systems could be the way to go. In these configurations, even if two systems fail simultaneously, the third can carry on without interruption.

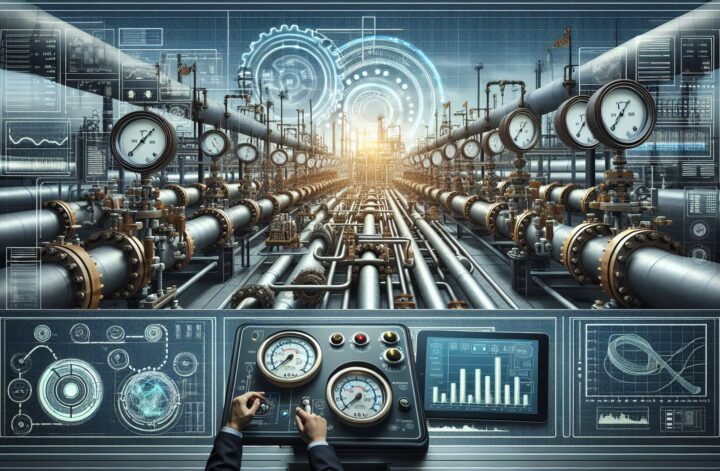

Modern technologies offer an array of solutions to incorporate redundancy into valve control systems. Virtualization and cloud-based systems mean that redundancies can be achieved without the need for duplicate physical systems. Within virtual environments, replication of control systems becomes effortless, making implementation of redundancy quicker, easier, and more cost-effective than ever.

The Commitment to Valve Control Redundancy

Implementing redundant valve control systems demands a commitment to a higher initial investment. However, this initial cost is often offset by considerably lower risk of downtime and drastic consequences of system failures. Redundant systems also improve reliability and longevity of the larger industrial system, contributing towards the overall operational cost-effectiveness in the long run.

However, embracing redundancy in valve control is not just about installing secondary systems. It is necessary to establish protocols for regular maintenance and testing of these backup systems. This will ensure that they are always ready to step in when needed.

Redundant valve control systems have become best practice in many industries, especially those dealing with hazardous materials or where precise control is required. Undoubtedly, where safety, continuity of service, and resilience against unexpected problems are important, valve control redundancy offers a proactive and effective solution.

Final Thoughts

As industries evolve and continue to leverage innovative automation technologies, the importance of redundancy in valve control systems will invariably increase. By prioritizing redundancy, industries of all types and sizes can safeguard themselves from potential system failures, ensuring a secure, trustworthy, and efficient working environment.

While redundancy might seem like an investment-heavy necessity now, the continuous evolution of technology promises to make these cost-effective and efficient solutions for all industries. After all, in a world where valve control plays a pivotal role in process automation, redundancy is not a luxury, but a requirement.

References: