Controlling valves manually was once the industry standard. Whether for turning on a residential sprinkler system or operating industrial-scale chemical plants, valves were commonly opened and closed by hand. But with the advent of automation technology and the need for increased productivity and effectiveness, automated valve control systems have become the norm, particularly in industrial settings. This article will delve deeper into valve control automation, examining how it enhances efficiency and reliability in various industrial operations.

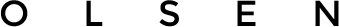

Valve control automation is the use of technologies such as electromechanical actuators, solenoids, or pneumatic systems to control the position of valves. This automation is typically managed through a central control system that can remotely command operations based on settings, sensors and programming inputs.

Increasing Efficiency with Automation

The efficiency of any process is determined by time, cost, and manpower. Automation in valve control effectively addresses all these factors. For instance, automating valve controls eliminates the need for manual operation, saving considerable labor costs and freeing up manpower for more critical tasks.

It also significantly reduces the time taken to perform tasks. Unlike the manual process, automated valves can open and close at programmable pre-set times, thereby reducing the “dead time” that often occurs in manual operations. This can assist in achieving a seamless, uninterrupted process flow, especially in industries such as petrochemicals or water treatment facilities.

Finally, automation can also contribute to cost savings as it reduces the need for frequent repairs or replacements linked to manual handling errors or wear and tear from regular usage.

Valve Control Automation for Reliability

One of the most significant benefits of valve control automation is its contribution to system reliability. Automated valve control systems are designed to ensure consistent, repeatable, and reliable operation. Regardless of the external operating conditions or the number of operational cycles, automated valve controls can deliver consistent performance because the control algorithms are pre-set.

Furthermore, valve automation provides enhanced remote capabilities, allowing operators to monitor and control operations from a centralized location. With feedback mechanisms, the system “communicates” operational data back to the control system. This communication aids in relieving any inconsistencies in the valve’s performance, further enhancing system reliability.

Selecting the Right Valve Control Automation System

While the benefits are evident, it’s essential that you choose the right valve control automation system for your specific application. Factors to consider include the size and type of the valve, the medium flowing through the valve, and the level of control required.

Also, consider the reliability of the control system in hazardous conditions, the flexibility to adapt to changing process requirements, and compatibility with your existing control systems.

In Closing

The functionalities and benefits of valve control automation are clear – enhanced efficiency and increased reliability. Whether it’s making existing operations cost-effective or designing new, advanced installations, automated valve control systems are an essential component.

When selecting an automation system, keep in mind the specific requirements of your operations. By doing so, the operational improvement and financial savings can be substantial.

In a world where competitive edge matters, valve control automation may just be the game-changer you are looking for. From leaner operations to more robust production capacities, automation is shaping the industries of tomorrow.

Sources:

Understanding Valve Design and Alloys

How Process Automation Systems can make your Company More Competitive