In our rapidly progressing digital era, many components of diverse industrial processes are transitioning from manual control to automated systems – and valve control is no exception. Valve control automation not only contributes to operational efficiency, optimal resource management, and improved safety, but is also significantly transformative in terms of financial savings and minimizing environmental footprint. This article aims to delve a little deeper into its nuances and why it should be a top priority in any modern industrial setup.

As an integral part of equipment systems, valves primarily control the flow and pressure of fluids. They come in various designs, types and sizes, each with its specialized capability. Manual control of these valves often necessitates skilled labor and can be time-consuming and prone to inaccuracies. However, advancements in technology have led the industry to embrace automation, including in the realm of valve control.

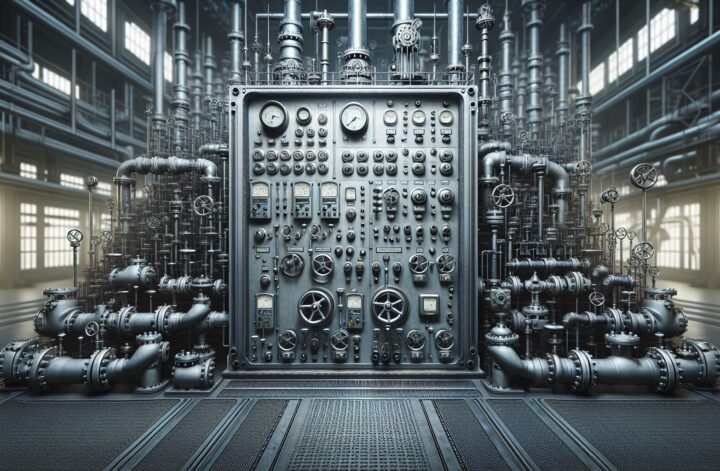

Automated valve control employs complex control systems, usually driven by software, which ensures precise, efficient, and reliable control of valves. The major components of an automated valve control system typically include an actuator, a positioner, and various other control instruments that can be configured to the specific needs of the operation.

One of the key benefits of automated valve control is continuous and precise control. With the help of sensors and software algorithms, these systems provide real-time control over valve operations, leading to enhanced accuracy and precision. Unlike manual control, automation inherently mitigates the risk of human error and ensures a higher level of consistency in valve operations.

Automation also paves the way for substantial safety improvements. Some valves handle dangerous and reactive chemicals, high pressures or extreme temperatures. Having workers manually control such valves exposes them to potential harm. Automated systems, however, can remotely monitor and control these valves, ensuring worker safety and operational compliance with various safety regulations.

Another high point of automated valve control is its predictive maintenance capability. In a traditional manual system, a failure or malfunction in a valve could lead to major system downtime and financial losses. But with automation, real-time monitoring and diagnostics means issues can be identified and rectified proactively, reducing system downtime, maintenance costs, and potentially serious industrial accidents.

Augmented with the power of data analytics, modern automated valve control systems can analyze performance data to optimize operations further. They can, for instance, dynamically adjust valve control parameters to optimize fluid flow as per changing requirements, thereby improving efficiency and resource utilization.

Considerations while implementing automated valve control systems should include the type and size of the valves, required control precision, nature of the fluids being handled, and operational environment. It’s equally important to ensure seamless integration with existing systems for maximum operational efficiency.

The initial investment in an automated valve control system might seem steep for some; however, the long-term savings and advantages far outweigh the upfront costs. From reduced labor costs and maintenance expenses to improved safety and efficiency, the benefits are manifold.

To sum up, automated valve control plays a pivotal role in the digital transformation of industrial processes by providing improved control precision, enhanced safety, and significant cost savings. As technology continues to evolve, the adoption of automated valve control is likely to become an operational necessity for every industry where fluid flow management is crucial.

So, next time you find yourself mulling over system upgrades, give automated valve control the serious consideration it deserves. As we continue to shape our work environments towards smart and efficient processes, choosing to automate our valve control can propel us closer to this goal.

References