No matter the size or type of your industry, optimization is at the heart of efficiency and productivity. In the world of machines and automated systems, valve control is pivotal, and optimizing these controls can reap the rewards of smoother operation, increased uptime, and reduction in maintenance costs. Today’s conversation brings us to valve control optimization as it forms the backbone of smart industrial processes.

Understanding Valve Control Optimization

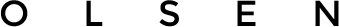

Optimization of valve controls refers to the fine-tuning of the valve parameters to achieve efficiency, swift response times, and accurate control of the flow of fluid in a pipeline system. Depending on the system’s design and purpose, these parameters could be about maintaining a certain pressure or temperature or controlling the flow rate or fluid level (source: Emerson).

Two key elements govern valve control optimization: the controller (device or software designed to manage the flow through the valve) and the actuator (the device that physically moves the valve to regulate the flow).

Why Optimize Valve Controls?

Optimization of valve controls is not just an optional extra – it comes with an array of benefits:

-

Energy Efficiency: Optimized controls lead to more efficient valve operation, translating into less energy use. In a world increasingly conscious of energy consumption, this is a massive plus.

-

Reduced Wear and Tear: An optimized valve system means valves are not subjected to undue stress, thereby prolonging their life and reducing maintenance needs.

-

Advanced Diagnostics: With optimization often comes more sophisticated diagnostics, making it easier to troubleshoot and maintain the overall system.

-

Better Performance: Optimization means the valves work at their best capacity, improving the performance of the entire system.

-

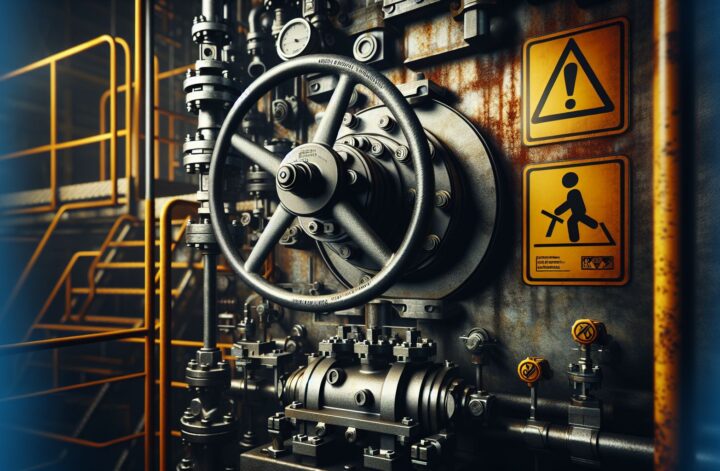

Safety Improvement: Efficient and optimized valves decrease the risk of unwanted accidents and equipment damage, increasing the plant’s safety level.

So how do we go about optimizing valve controls?

Approaches to Valve Control Optimization

Optimization strategies usually involve a mix of best practices, advanced algorithms, and regular maintenance:

-

Valve Sizing: Proper valve sizing is fundamental to optimizing valve performance. The valve size should correspond to the flow requirements to ensure efficient operation.

-

Choice of Actuator: The type of actuator used can highly influence valve response times and efficiency. A good match between the valve and actuator can optimize performance.

-

Condition Monitoring: This strategy involves regular checks and monitoring of valve conditions, including measurements of vibration, temperature, and sound.

-

Predictive Maintenance: By collecting and analyzing data from valves, potential faults can be predicted and dealt with before becoming serious issues.

-

Advanced Control Algorithms: Use of advanced control algorithms can significantly optimize the performance by adjusting in real-time to keep the control system at its optimal operating point.

-

Training: Lastly, properly trained personnel can spot issues earlier, interpret diagnostic data more accurately, and carry out optimized control practices more effectively.

Conclusion

In a world becoming more and more automated, optimizing valve controls is a crucial step towards industrial efficiency. While it requires an upfront investment in specialized equipment and software, the long-term benefits in terms of cost savings, improved efficiency, and equipment longevity can not be overemphasized.

This complex process might require consultation or collaboration with specialized teams or companies that provide valve control optimization services, but the bounty of benefits outlined above makes a compelling argument for making the leap into the age of optimization (source: Science Direct).

With careful planning and execution, valve control optimization can make your production more efficient, safe, and productive. The world has fast-tracked its journey towards automated and optimized systems, and it’s high time we stay on pace.

And remember, the optimization shouldn’t stop at valves – it should be carried throughout the entire system for maximum benefit. Indeed, with every optimized component, we’re one step closer to a more efficient, sustainable, and safer future.

So, ready to optimize your valve controls? Let’s make the change for a brighter industrial future.

Sources:

1. Control Valve Optimization – Emerson

2. Sustainable Industrial Processing – ScienceDirect.