Valve control diagnostics is an aspect of valve management that often doesn’t get the attention it merits. If there’s something irregular going on within your valve control system, then definitively, something’s awry that needs prompt attention. It’s like your body signaling when something’s off, and you need to see a doctor. Valve control diagnostics is that handbook and health check that keeps your entire valve control system fit and robust.

And guess what? In today’s post, we will demystify valve control diagnostics – breaking down its nuts and bolts, highlighting its importance, and lastly, easing into some practical tips to help optimize your system.

What is Valve Control Diagnostics?

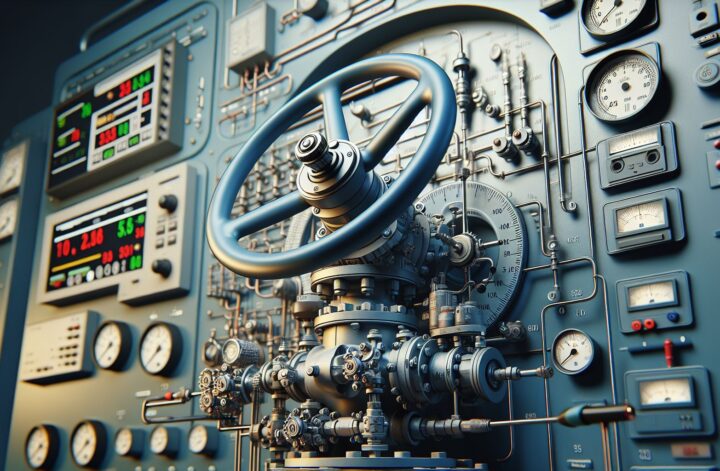

Valve control diagnostics refers to a variety of techniques used to evaluate the performance and condition of valves within a control system[^1^]. It involves the use of monitoring software, various diagnostic tools, and algorithms that detect abnormalities and changes within the system.

Simply put, think of it as the ‘doctor visit’ for your valve control system. It entails routine checks to ensure everything’s working optimally, and if not, it pinpoints the likely problems for quick fixing.

Why Valve Control Diagnostics Matter?

You may think, “All’s well as long as my valve control system runs without hitches.” Is that the case really? Here’s why a reconsideration may be prudent.

Operational Efficiency

Routine diagnostics contribute significantly to maintaining high operational efficiency. You see, over time, wear and tear, dust accumulation, or even software bugs can slow down the performance of your valve control system. Regular monitoring ensures these issues are nipped in the bud, keeping your system running swiftly and efficiently.

Preventive Maintenance

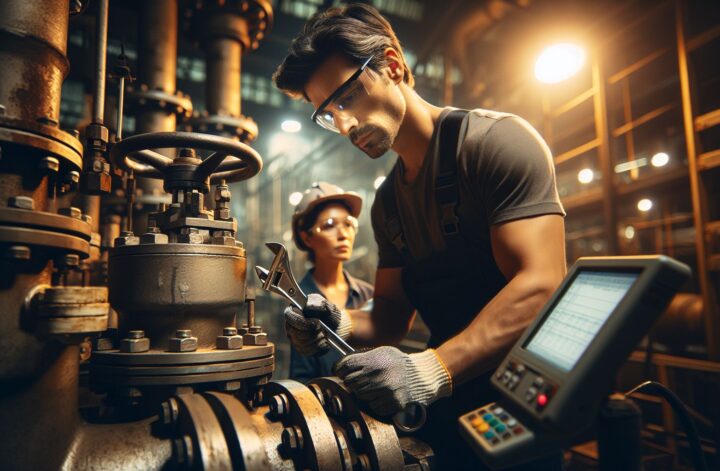

Think of valve control diagnostics as a vaccine given to your control system. With regular check-ups, you can identify potential problems before they balloon into costly repairs or replacements. It will also help expand the life expectancy of the system.

Safety

In any industrial operation, safety is paramount. Faulty valve operations can lead to catastrophic outcomes, including fires, chemical spillage, or other environmental hazards. Regular diagnostic checks help maintain safety standards by ensuring that all components within the control system function correctly[^2^].

Practical Tips to Optimize Your Valve Control Diagnostics

Alright! Now, since you understand the significance of valve control diagnostics, here are some handy tips to ensure you make the most out of it.

Regular Monitoring

Set a schedule for regular valve control diagnostics and stick to it. Depending on your operations’ nature, you may need daily, weekly, or monthly checks.

Invest in Quality Diagnostic Tools

Quality diagnostic tools with updated software will give you accurate feedback about your valve control system. A professional service provider can help you decide which tools are appropriate for your operations.

Employ Expert Services

If your team lacks the necessary expertise to conduct detailed diagnostics, consider outsourcing the service to a professional diagnostics company. They have the experience and tools to conduct thorough diagnostics and interpret the results accurately.

Keep Logs

Always record the results of your diagnostics. These logs can help you track the system’s performance over time, identify patterns, and predict future problems.

Team Training

Invest in training your team to understand valve control diagnostics. It enhances their capacity to monitor the system, conduct simple fixes, and when necessary, alert you to seek professional help.

In conclusion, valve control diagnostics is typically your vault door to the seamless and proficient running of your valve control system. Looking at the symptoms and causes concurrently, it helps to maintain efficient operations, stimulate preventive maintenance, and boost overall safety.

In a nutshell, your valve control diagnostics is the canary in the coal mine, and to overlook it is business hara-kiri that one wouldn’t wish even on their most dreaded competitor. So buckle up, and let’s keep that system optimally functioning.

Stay tuned for more posts, plotting the course to flawless valve management, and keep those systems spick and span!