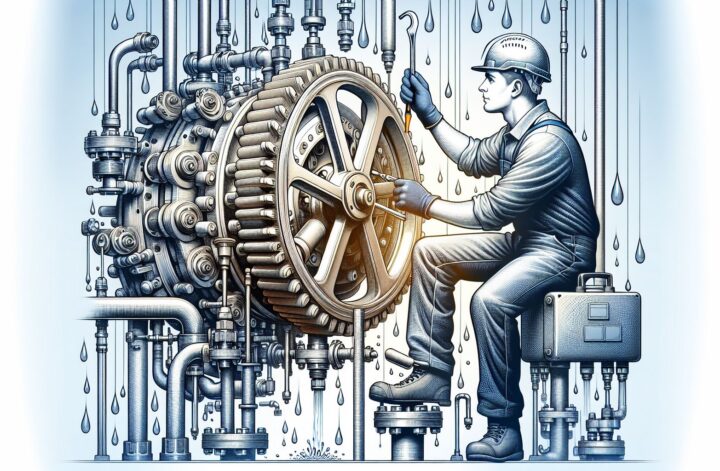

When it comes to ensuring the smooth functioning of your industrial operations, valve control systems may not be the first thing on your mind. However, they play an integral role in controlling the flow of fluids in a wide range of process applications. These can range from oil and gas plants, petrochemical and chemical facilities, to water treatment plants and power generation stations. And like any other mechanical device, valves require regular maintenance to keep them operating at their peak performance.

Here’s a deep dive into the importance of valve control maintenance, the common issues to look out for, and the best practices for maintaining your valve control systems.

A Few Basics.

Valve control systems come in a variety of types, including manual, hydraulic, pneumatic, and electric. Each type has its benefits, depending on the specific industrial application. Regardless of the type of valve control system in use, regular maintenance is vital. Timely maintenance can prevent unplanned downtime, prolong the service life of the valve, and ensure optimal process performance.

The Common Culprits

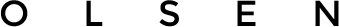

One of the main issues which require constant maintenance in valve control systems is leaks. Leaks can occur due to wear and tear or due to improper installation or misalignment. If left unchecked, these leaks can lead to significant fluid loss, pressure issues, and even pose serious safety risks.

Another common issue is the buildup of deposits within the valves. Over time, these deposits can hinder the valve’s movement, affecting the smooth operation and control accuracy of the entire system.

Best Practices for Maintaining Your Valve Control Systems

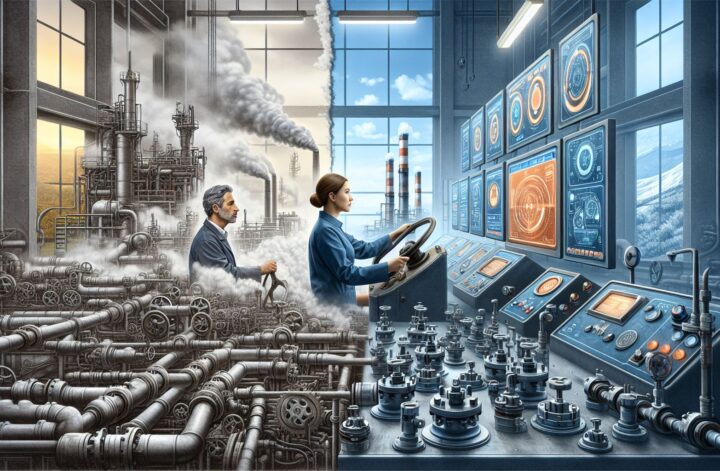

Routine Inspection: Regular inspection should be a part of your maintenance program. Regular inspections can help identify potential problems before they escalate, saving time, money, and trouble down the line. During inspections, pay attention to any signs of leakage, identify any unusual noises, and check for any physical damages.

Timely Repairs: Once an issue has been identified, prompt and corrective action is necessary. This may involve replacing worn-out parts or fixing any misalignments. Remember that a less costly repair now could prevent a much more expensive problem down the line.

Regular Cleaning: Ensure the valves are regularly cleaned to prevent deposits from affecting their functionality. It is important to use the right cleaning method depending on the material of the valve to prevent damage.

Lubrication: Regular lubrication is essential to ensure that the moving parts of the valve function smoothly. Always use a suitable lubricant based on the valve material and the specific industrial application.

Professional Help: While regular maintenance can be carried out by the in-house team, it is advisable to involve qualified professionals especially for in-depth inspections, complex repairs, and replacements. They can provide expert insights and help prolong the life of your valve control systems.

Documentation: Keep a record of all maintenance activities. This can be in the form of a log book or using modern valve maintenance software. Documentation can be of great use in troubleshooting and future maintenance planning.

Reminder

Valve control systems are more than just mechanical devices; they are a critical part of your industrial processes. By complying with a robust maintenance program, you can expect a longer service life from your valves, higher operational efficiency, improved safety, and, ultimately, increased profits.

Remember, the key to effective valve control maintenance is prevention and not just cure. By regularly inspecting your systems and addressing minor issues as they arise, you can prevent major problems that could result in substantial downtime and costs.

Paying attention to valve control maintenance may not be the most glamorous part of your operations, but it certainly is an imperative. It’s time we give these small yet significant components the attention they deserve.