In today’s fast-paced industrial landscape, everything is centered around efficiency and precision. One area that has seen considerable innovation is valve control. If you’re in a sector that involves fluid control systems, like manufacturing or processing, you’re no doubt familiar – and possibly a bit obsessed – with optimizing your valve controls.

Enter the magic of ‘Valve Control Automation.’ This modest phrase stands for a revolutionary concept that has changed the face of industrial operations.

The Beauty of Automation

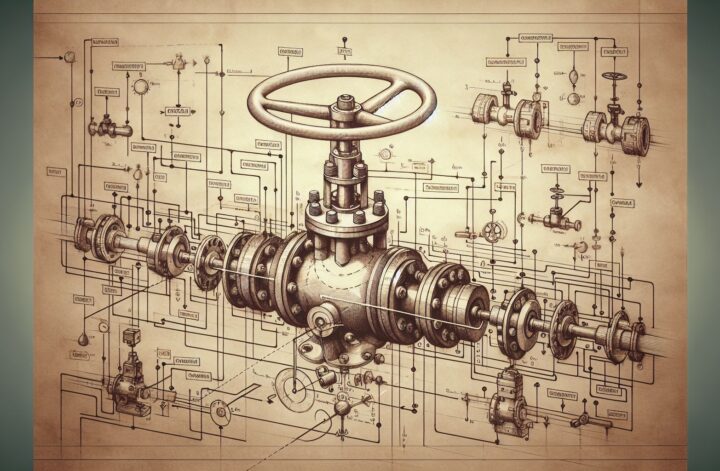

Valve control automation refines the process of modulating the flow of fluids or gases in pipes and ducts. Traditionally, valves needed to be manually adjusted, a process that posed several challenges arising from human error, slower response times, and difficulties in scaling.

But thanks to advances in technology, particularly in fields like IoT (Internet of Things) and AI (Artificial Intelligence), automation has entered the picture. Now, we can have systems that control valves — opening, closing, or modulating — according to pre-set conditions, without requiring any human intervention (1).

What does it Involve?

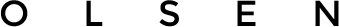

Automation in valve control broadly involves integrating a centralized software with valve actuators and sensors. The sensors help measure parameters like fluid pressure, flow rate, or temperature. When these parameters hit a particular threshold, the software directs the actuators to adjust the valves accordingly.

For instance, suppose a specific operation required reducing the steam pressure when it reached 15 psi. In traditional systems, an operator needed to constantly monitor the pressure gauges and manually adjust the control valves to regulate steam flow when the gauge indicated 15 psi. With an automated system, sensors would continuously measure steam pressure and communicate this information to the centralized software. When this software perceives a pressure of 15 psi, it will automatically direct the actuator to adjust the valve, thus regulating the steam pressure.

How Does Valve Control Automation Benefit Industries?

Automation in valve control offers a multitude of benefits:

-

Increased Efficiency: Automation increases operational efficiency by enabling swift responses, thus minimizing the risks of damage caused by delays or error in manual adjustments.

-

Enhanced Safety: In industries where hazardous substances are used, the misuse of control valves can lead to dangerous situations such as spills or explosions. Automatic valve control significantly reduces these risks.

-

Reduced Operational Costs: Although initially the setup cost might seem significant, automated systems generate considerable savings in the long run by reducing labor costs, maintenance costs, and the risk of operational accidents.

-

Scalability: Since the process of valve control is directly handled by the software, the capacity can be easily scaled up based on the process requirements (2).

-

Improved Data Collection and Reporting: Automated systems can provide comprehensive data for process analysis, aiding in decision-making and facilitating process improvements.

Is Valve Control Automation For Your Setup?

The degree of automation needed often varies based on the complexity of the operations, budget, and other operational demands. For simpler processes, semi-automated might be adequate, while more complex systems might require complete automation. But overall, if you’re looking for improved operational efficiency, cost reduction, and enhanced safety, it’s definitely worth considering automation for your valve control.

In an era where industries are constantly on the look-out for ways to improve efficiency and safety, valve control automation is truly a game-changer. Blending technology-driven processes with industry-specific needs, it offers a way to keep pace with the competitive industrial landscape.

So, are you ready to embrace the future?

Referenced Sources

-

Yokogawa, “Industrial Automation and Control Solutions from Honeywell,” Yokogawa Electric Corporation

-

Rockwell Automation, “Control and Visualization on One Hardware Platform,” Rockwell Automation