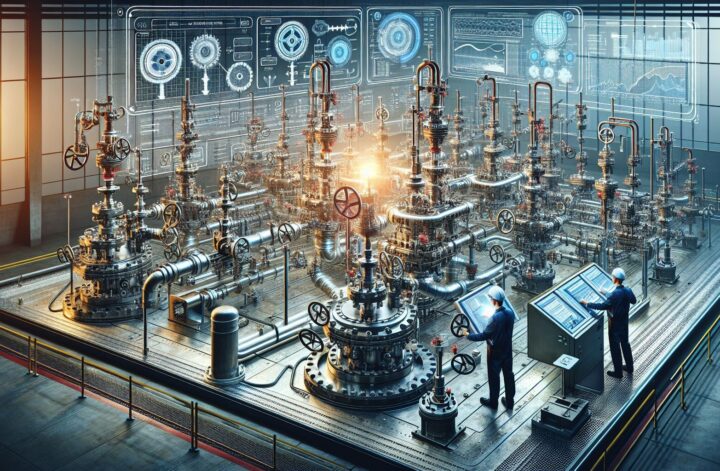

The profound benefits of automation have permeated almost every aspect of our lives, with the industrial sector being no exception. Particularly, automation in valve control has been a game-changer, significantly optimizing processes and improving operational efficiency. Whether it’s in the oil and gas sector, power generation, chemical manufacturing, or even food processing, valve control automation has found widespread applications.

What is Valve Control Automation?

Valve control automation involves the use of computer-based systems or automated means to control, monitor, and optimize the operation of valves in different industrial processes. Automation in valve control presents immense benefits, including greater efficiency, enhanced reliability, reduced manpower, and the potential for remote operation.

Advantages of Valve Control Automation

Operational Efficiency

In traditional setups, operations such as opening, closing, or adjusting valve settings are done manually. But with automated valve control, these processes can be done more rapidly and precisely, leading to increased operational efficiency. Automated systems can swiftly react to process changes, optimizing both time and energy consumption.

Improved Safety

In industries dealing with hazardous substances, manual valve control could exposé staff to potential health and safety risks. Automated valve control minimizes human contact, significantly enhancing workplace safety.

Reduced Operational Costs

Manual valve control often demands substantial effort and manpower. An automated valve control setup can effectively trim down resource utilization on mundane tasks, thereby drastically reducing operational costs.

Remote Operation

The advent of the Internet of Things (IoT) has embedded automation into seamless network systems enabling remote operations. In sectors such as oil and gas where offshore plants are prevalent, remote control and monitoring of valves can be a boon.

Accuracy and Precision

Automated valve control systems maintain higher accuracy and precision compared to manual control systems, which are prone to errors. This precision improves product quality and minimizes wastage.

Predictive Maintenance

Automated valve control systems often come with built-in diagnostic tools that can predict maintenance needs, averting costly downtime.

Implementation of Valve Control Automation

When planning to automate your valve control system, it is vital to take a comprehensive approach to ensure a successful integration.

-

Needs Assessment: Identify the requirements of your system and match these against the benefits and capabilities of valve control automation.

-

Technological Overview: Evaluate the existing systems and controls in your setup. This gives a realistic picture of what is attainable and the kind of modifications necessary.

-

Finding the Right Integrator: Choose an experienced integrator who can customize the automated valve control system according to your specified needs.

-

Training and Support: Post-installation, ensure that operators and maintenance personnel receive adequate training.

-

Continuous Evaluation and Upgrade: Regular evaluation ensures the automation system is functioning as intended. Upgrades cater to evolving operational requirements.

Automated valve control is no longer a fancy add-on but a necessary tool for industries to keep up with the competitive global landscape. Prioritizing automation in your valve control system can lead to considerable gains in terms of safety, productivity, efficiency, and cost savings. While the initial investment may seem steep, the long-term benefits undoubtedly outweigh the costs.

As automation continues to evolve, we can expect even more exciting advancements in the field of valve control automation. By embracing modernization and constantly striving for efficiency, industries can unlock the full potential of automated systems and set a new benchmark in operational excellence.

Sources:

1. Automated Valve Control Systems: An Overview

2. Valve Control Automation in Industrial Processes: A Case Study