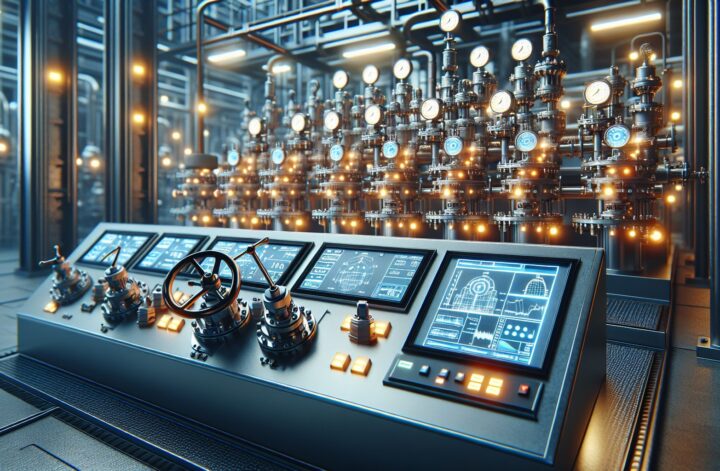

Hello there! Today, we explore the intriguing world of valve control automation and how it’s revolutionizing industries one valve at a time. Whether it’s controlling the flow of steam in a power generation facility or managing the amount of oil flowing through a pipeline, automated valves play a crucial role in many industrial operations—and rightly so!

What is Valve Control Automation?

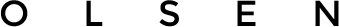

Valve control automation, in a nutshell, involves equipping standard valves with automatic actuators that can operate them without human intervention. These automated controls can be programmed to execute specific actions based on predefined parameters or triggered by feedback received from the system. So, rather than depending on a human operator to manually manipulate the valve, automated systems utilize advanced software algorithms and mechanical components to efficiently manage the process. Modern automation systems offer high accuracy, precision, and speed, thereby reducing the margin for error significantly[^1^].

How Does Valve Control Automation benefit Industries?

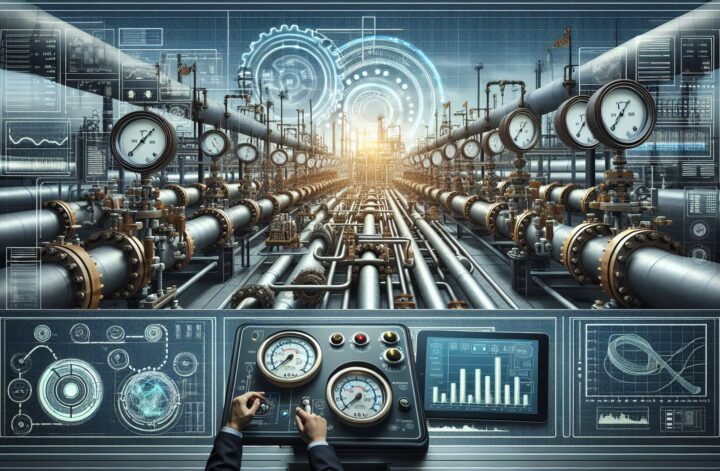

Enhancing Safety and Reducing Human Errors

Safety is paramount in any industrial environment. Automated valve control systems are designed to minimize human interaction, which, in turn, reduces the risk of accidents. The implementation of this technology almost eradicates the chances of errors caused due to negligence, miscommunication, or incorrect manual operation.

Time and Cost-Effective

Valve control automation systems can quickly respond to changes in system parameters, reducing the lag time involved with manual operation. This rapid response can prevent equipment damage and reduce costly downtime. Moreover, with less reliance on human operators, labor costs are cut significantly.

Efficient Operation and Maintenance

Automated valves come with advanced diagnostics that monitor parameters like valve status, position, and leakages, plus potential mechanical issues. Regular monitoring facilitates preventative maintenance and avoids unexpected malfunctions. Further, automation increases the overall efficiency of an operation by ensuring optimal operation at all times.

The Future of Valve Control Automation

As industries continue to adopt automated systems, the future looks promising for valve control automation. Enhanced system integration capabilities, improved diagnostic tools, and the introduction of more intelligent automation strategies are expected to drive this market further[^2^].

Valves with ‘smart’ capabilities are the future — these can monitor real-time system parameters, adjust operations based on the data collected, and even alert operators of potential issues. Also, it’s fair to anticipate a future where the integration of machine learning and artificial intelligence with valve control automation leads to even more efficient and reliable operations.

The inevitable realization is that valve control automation is more than a luxury—it’s an essential aspect of modern industrial operations. Understanding the full capability of this technology and implementing it effectively will be a game-changer for industries worldwide. So, stay tuned to the latest developments in this field, as they’re bound to make waves in the world of automation.

In a world pushing for automation, learning about concepts like valve control automation is not only fascinating but also crucial — and I hope this blog post has helped you on that front. Remember, automation isn’t just about convenience. It’s about efficiency, safety, and the continuous progression of our industries and the world at large.

Until next time, stay curious, and stay informed!

[^1^]: A Guide to Automatic Control Valves

[^2^]: Valve Controllers Market – Growth, Trends, COVID-19 Impact, and Forecasts (2021 – 2026)