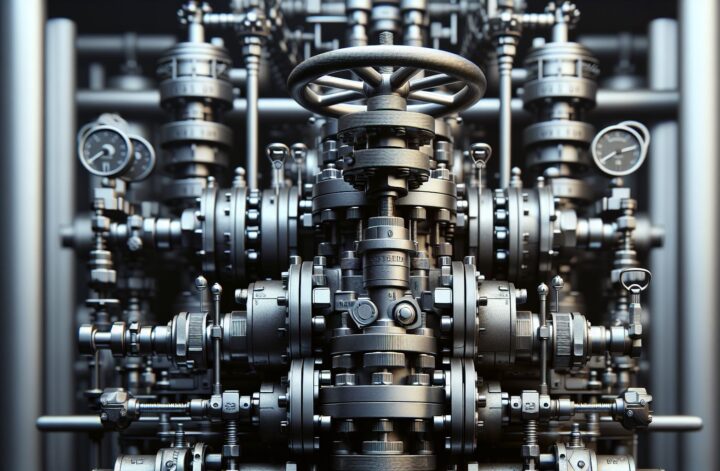

The world in which we live today is governed by a complex network of systems and subsystems, all meticulously designed to function together. From temperature control in a home to transportation systems, and from industrial production to advanced computing, every system around us demands accuracy from its various components. It’s with this spirit of precision that we delve into the world of industrial automation, specifically looking at valve control accuracy.

A seemingly simple yet undeniably crucial component, valves are practically everywhere. They help control the flow of various substances across any system, be it gas, liquids, or even certain solids. To get a sense of just how important they are, imagine having a faucet in your home that doesn’t close properly – the resultant leak can cause enough trouble, let alone the potential headaches that inaccurate valve control can cause in an industrial setup. To prevent such mishaps and save valuable resources, the accuracy of valve control has become an increasingly critical area of focus in the industrial automation world.

The Importance of Valve Control Accuracy

Valve control accuracy is essentially about ensuring that a valve responds correctly to given commands. If a control system commands a valve to open or close to a specific degree, accuracy involves achieving the exact requested state. It tells the control system the exact position of the valve.

Improper or inaccurate valve control can lead to various problems. It can cause inefficiencies in the system, safety hazards, and unnecessary equipment wear and tear. Efficiently working accurate valve control not only increases the overall efficiency of the system but also ensures the longevity of the system components, leading to cost savings in the long run[^1^]

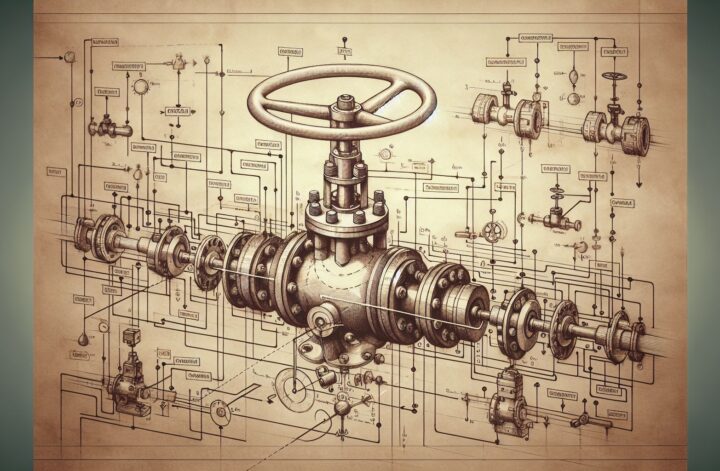

An essential aspect of optimizing valve control accuracy is the use of efficient valve control algorithms. These algorithms help make precise adjustments to valve control mechanisms, ensuring exact adherence to control system commands[^2^].

Steps to Enhance Valve Control Accuracy

Achieving accurate valve control isn’t always straightforward and largely depends on various factors ranging from the quality of the control components used, the effectiveness of control algorithms, and the overall system design. However, a few key considerations can help enhance the accuracy of valve control:

- Regular Calibration: Regular calibration of valve control systems can help ensure that they’re functioning accurately. Depending on the usage and criticality, the valves should be calibrated periodically.

- Quality Components: The accuracy of a valve control system is also significantly influenced by the quality of the system’s various components, including the valve itself, sensors, actuators, and any other control components.

- Effective Control Algorithms: Incorporating effective and efficient control algorithms can enhance the overall accuracy of a valve control system. Such algorithms can also learn from any errors or discrepancies and adapt to deliver enhanced accuracy.

- Monitoring and Maintenance: Continuous monitoring and maintenance are also essential aspects of enhancing valve control accuracy. An effective monitoring system can help identify and rectify any problems early on, before they escalate and cause serious system malfunctions.

The accuracy of valve control is an essential mix of technology, industry best practices, and meticulous attention to detail. But when executed well, it can provide significant advantages, from enhanced system efficiency and longevity to savings in costs and resources.

[^1^]: Valve Diagnostics: Unearth the Facts on Your Actuation. (Valve Magazine). Retrieved from: link

[^2^]: Valve control algorithms in control systems. (Plant Engineering) Retrieved from: link